17

YEARS OF EXPERIENCE

BAOWU

Our Introduction

Welcome to Baowu steel

Shandong Baowu Steel Co., Ltd. remains committed to its foundational principle of prioritizing quality and building its reputation for reliability. Placing integrity and quality at the forefront, the company embraces a win-win philosophy and maintains a customer-focused approach, aspiring to be your reliable partner

- Optimized Production Strategies

- Technological Advancements

- Rigorous Quality Assurance

- Environmental Responsibility

- Strategic Supply Chain Optimization

- Client-Focused Strategy

Call to ask any question

Our benefits

HIGN QUALITY STEEL FOR YOUR INDUSTRIES

Superior steel offerings cement customer confidence. Clients who depend on the robustness, longevity, and strict specification adherence of your products tend to repeat business and refer others.

01

Diverse and Customizable

02

ntegrated Services Support

03

Baowu Steel promises to recycle unqualified products

Why Choose us

Hot product

-

Stainless steel threaded rod

Read more -

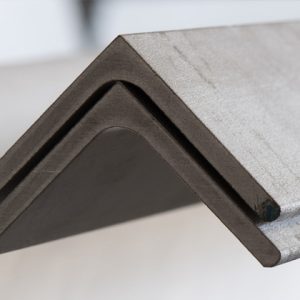

Carbon steel angle

Read more -

Stainless steel angle

Read more -

Stainless steel channel steel

Read more -

Stainless steel H steel

Read more -

Carbon steel channel steel

Read more -

Galvanized pipe

Read more -

Galvanized steel coil

Read more -

Stainless steel pipe

Read more -

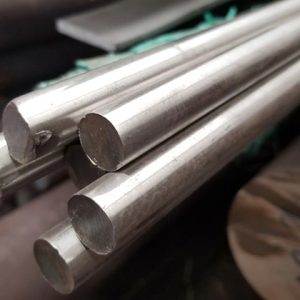

Stainless steel rod

Read more -

Carbon steel rod

Read more -

Carbon steel coil

Read more -

Carbon steel pipe

Read more -

Aluminum rod

Read more -

Aluminum tube

Read more -

Aluminum plate

Read more

What we have

advanced equipment on steel plate

steel coil steel pipe processing

real facts

Company building

Projects done

EXclusive partners

Happy clients

science management

carbon steel Real-Time Process Monitoring:

Implementing sensors and control systems that provide continuous feedback during the manufacturing process, allowing for immediate adjustments to maintain quality standards

Carbon steel AI and Machine Learning

These technologies are used to predict material properties and behaviors based on historical data, which can optimize the carbon content and heat treatment processes to achieve

Aluminum steel Environmental Control

Advanced HVAC systems that control the environment in manufacturing facilities to prevent contamination during the coating process, ensuring uniform application

Aluminum Coating Technologies:

Developing new methods of coating aluminum onto steel to enhance corrosion resistance while maintaining the structural integrity and lightweight properties of aluminum

Stainless steel Precision Alloying

Using precise measurements and controls to add alloying elements such as chromium, nickel, and molybdenum, which are critical for forming the passive layer

Stainless steel Automated Quality system

Automated systems for defect detection and quality assurance, using technologies such as ultrasonic and eddy current testing to ensure that the products meet stringent specifications

Hot-Dip Galvanizing Process Control

Enhancements in the control of the hot-dip galvanizing process, including better temperature control and more efficient use of zinc baths, to improve coating quality

Galvanized Corrosion Performance Modeling

Advanced modeling tools that predict how long a zinc coating will protect the steel under various environmental conditions, which helps in designing more durable products

What we offer

Shipment & Inspection

Channel steel dimension

H steel dimension

Angle steel dimension

Channel steel dimension

Steel rebar dimension

H steel dimension

Angle steel dimension

What we offer

FAQ & CONTACT US

Chinese stainless steel factories have invested heavily in state-of-the-art precision alloying and continuous casting technologies. This allows for the production of high-purity steels with consistent properties, positioning China as a leading exporter of stainless steel.

China leads in carbon steel production due to its integration of smart manufacturing practices. Chinese factories utilize advanced AI-driven analytics to optimize furnace temperatures and chemical compositions, ensuring high-quality output at lower costs.

Chinese manufacturers use advanced hot-dip galvanizing techniques with precise temperature control and automated zinc layer monitoring systems. This results in a more uniform and durable zinc coating, which is crucial for preventing corrosion.

Aluminum steel producers in China are pioneering new coating methods that enhance adhesion and corrosion resistance. These advancements include using nanotechnology to improve the bonding of aluminum layers to steel substrates.

China has made significant strides in implementing environmentally friendly steel-making processes. This includes adopting electric arc furnaces (EAFs) and utilizing by-product gases, reducing the carbon footprint per tonne of steel produced compared to many other major producers.

Through rigorous implementation of automated and computerized quality assurance systems, including real-time X-ray fluorescence (XRF) and ultrasonic testing, Chinese steel plants maintain a high standard of product quality and uniformity.

News

Global iron ore supply and demand are expected to ease slightly in 2024

Macroeconomic expectations have dominated the market recently, spot prices have continued to rise, regulatory pressure has increased sharply, iron ore’s own driving

26 Chinese shipyards accept orders! Container ship new ship orders hit record high

The hot market in the container shipping market has led more and more shipowners to “rush

Baowu Steel Company Revolutionizes Industry Standards with Environmental Initiatives and Advanced Processing Technologies

[Shandong, 2021-7-12] — In a pioneering effort to redefine the steel manufacturing industry, Baowu Steel Company has announced a series

Baowu Steel Leads the Way in Advanced Thin Carbon Steel Plate Technology Training

[Jinan,2020-4-16 ] — In a bold move to spearhead innovation and expertise within the manufacturing industry, Baowu Steel has launched